As part of our ongoing efforts to create continuous improvement in our company, our process and our product, we have recently worked with the Michigan Manufacturing Technology Center (MMTC) to run a couple of Kaizen events.

The first Kaizen event took place in August focusing on our aluminum fabrication department. The second one took place in October, focusing on shipping and receiving. A third one is scheduled to go over our quality process. Eventually, we will do one for every part of the plant and even some departments in our home office.

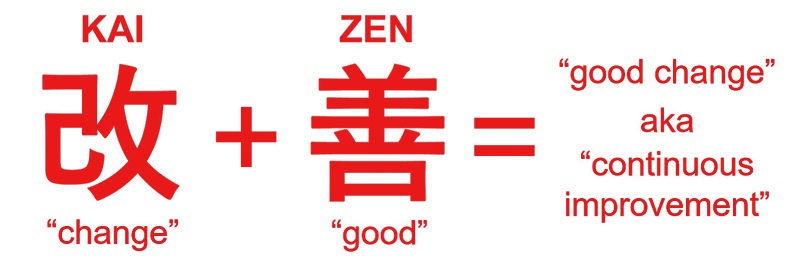

Kaizen is a Japanese word meaning “good change.” Toyota referred to it as “continuous change” and used it in the 80s to improve quality and efficiency. Today, it’s part of lean manufacturing. It helps a company find and eliminate issues, shorten lead times and eliminate waste – both in materials and process. It is not a tool for eliminating people or demanding more without providing tools and strategies to do so.

A Kaizen event involves all of Total Door’s area experts, the plant manager, members of the executive team and the people who actually work in the area we are focusing on. It begins with a brainstorm outlining the things we want to address and areas that are of concern. Then we go into that area of the plant and start mapping out the processes involved.

For instance, in the aluminum fabricating area, we used the Kaizen process to look for where there was waste, including waste of movement. What does overproduction add into the process? How much waiting time is there and what does it add to the process? How does the layout affect it? We did a spaghetti diagram to see if there was too much time walking around in the process and adjusted the work flow.

Once we had the data and a plan of action, we went to work. We cleaned the whole area and got rid of old and outdated materials that no longer added to the process or needed to be there.

When we were done, we had 15 items to follow up on. It took us 30 days to achieve them. But it was well worth it. The department before this struggled to get a good score in our weekly 5S (Sort, Set In Order, Shine, Standardize and Sustain). Since our Kaizen event, it has consistently gotten 100% in their 5S. They are doing a great job following the new processes and keeping everything in it’s place.

By the time we have completed an event for every department, we will not only see improvement that everyone has been involved in, but we will have documented, sustainable, repeatable processes and procedures that will help when something new comes our way.

This is important since our business is all about creating customized doors. Things change every manufacturing cycle. Having processes in place that everyone is familiar with will keep us creating new and better products, no matter what your clients need in the future.